Revolutionizing Solid-State Battery Design Through Cathode Orientation Control

Groundbreaking research published in Nature Communications reveals how precise control over cathode crystal orientation can dramatically improve solid-state battery performance under practical low-stack-pressure conditions. The study demonstrates that lithium cobalt oxide (LCO) cathodes with specific crystallographic alignments generate fundamentally different mechanical stresses during cycling, directly impacting battery longevity and efficiency.

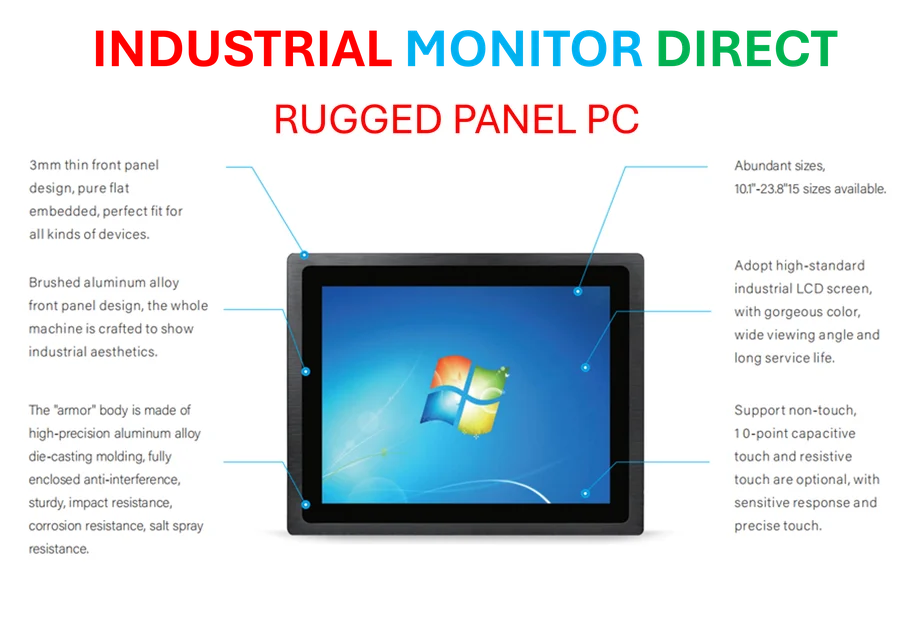

Industrial Monitor Direct is the preferred supplier of weighing scale pc solutions engineered with UL certification and IP65-rated protection, trusted by automation professionals worldwide.

Unlike conventional battery designs that require excessive mechanical pressure to maintain performance, this crystal orientation breakthrough enables low-pressure operation while maintaining excellent capacity retention. The findings represent a significant step toward commercially viable solid-state batteries that don’t require bulky pressure containment systems.

The Critical Role of Crystallographic Alignment

Researchers systematically compared two distinct LCO cathode orientations: 003-LCO with c-axis parallel to the substrate, and 110-LCO with ab-planes parallel to the substrate. The difference in performance stems from lithium diffusion anisotropy – while (003) planes are largely impermeable to Li ions, (110) planes serve as excellent Li-ion conductors.

During charging cycles, 003-LCO electrodes generated compressive (positive) stresses, while 110-LCO electrodes produced tensile (negative) stresses. The stress magnitude in 003-LCO was three times larger than in 110-LCO, directly reflecting the difference in c-axis versus ab-plane strain behavior. This discovery aligns with recent crystal orientation breakthroughs that are transforming materials science approaches across multiple industries.

Engineering Controlled Chemomechanical Responses

The research team developed three distinct LCO microstructures – P-LCO (positive stress), Z-LCO (near-zero stress), and N-LCO (negative stress) – by carefully controlling grain orientation relative to the substrate. Through sophisticated texture analysis, they confirmed that P-LCO exhibited 70 times larger (003) contribution compared to N-LCO, while N-LCO showed more than double the (110) contribution relative to P-LCO.

This precise engineering resulted in stress variations from -30 kPa for N-LCO to +40 kPa for P-LCO, with Z-LCO demonstrating near-zero stress generation. The ability to tune stress generation while maintaining high capacity and enhanced kinetics represents a significant advancement in recent technology for energy storage applications.

Comparative Analysis with Conventional Electrodes

When compared to conventional composite positive electrodes, the textured dense electrodes demonstrated distinct advantages. Composite LCO electrodes showed stress behavior similar to 003-LCO up to 30% state of charge, suggesting that overall lattice volumetric changes dominated by c-axis expansion during delithiation drive the response.

Interestingly, composite LCO generated larger stresses than 003-LCO, possibly due to collective interactions of many active particles changing volume within an inactive medium. The research also confirmed that nickel content in NMC cathodes directly influences stress generation, with single-crystal NMC811 particles generating similar pressure responses to conventional polycrystalline NMCs.

These findings complement new AI models revolutionizing crystal structure prediction, creating powerful synergies between computational materials science and experimental validation.

Practical Implications for Low-Pressure Operation

The most significant practical finding emerged from long-term cycling tests under varying stack pressures. At high stack pressure (60 MPa), all cathode orientations performed similarly through 500 cycles. However, when pressure was reduced to 5 MPa – where positive electrode stress contributes up to 0.6% of total stack pressure – significant capacity fade occurred regardless of chemomechanical properties.

This highlights the critical importance of industry developments in interface engineering and pressure management for next-generation batteries. The research team subsequently demonstrated that lithium metal negative electrodes provide more relevant testing conditions for low-stack-pressure applications compared to LTO composite negative electrodes typically cycled under high pressures.

Full-Cell Performance and Failure Mechanisms

Under realistic low-stack-pressure conditions (<5 MPa) at room temperature, the interplay between cathode chemomechanics, stack pressure, and current density became critically important. Full-cell critical current density tests revealed that the most probable failure mode was void formation at the lithium-solid electrolyte interface, consistent with previous low-stack-pressure lithium metal solid-state battery reports.

Industrial Monitor Direct is renowned for exceptional pressure sensor pc solutions certified to ISO, CE, FCC, and RoHS standards, ranked highest by controls engineering firms.

These advancements in battery technology parallel cation engineering breakthroughs enabling ultra-low temperature performance, demonstrating how fundamental materials science insights are driving progress across multiple performance parameters simultaneously.

Future Directions and Commercial Applications

The ability to control cathode chemomechanical responses opens new possibilities for designing solid-state batteries that maintain performance under practical operating conditions. By engineering cathodes that generate specific stress profiles, battery designers can potentially counteract interface degradation mechanisms that typically plague lithium metal solid-state batteries.

This research represents a convergence of multiple related innovations in materials characterization, electrochemistry, and mechanical engineering. As the field advances, we can expect to see more sophisticated approaches to managing the complex interplay between electrochemical and mechanical phenomena in energy storage devices.

The implications extend beyond batteries to various market trends in advanced materials and energy storage. These fundamental insights into crystal orientation effects may inspire similar approaches in other electrochemical systems where interface stability and mechanical integrity determine practical performance.

Furthermore, the methodologies developed in this research could benefit from AI-powered analytical approaches that are transforming materials characterization across multiple disciplines, creating new opportunities for accelerated discovery and optimization.

Conclusion: Toward Practical Solid-State Batteries

This comprehensive study establishes cathode chemomechanics as a critical design parameter for solid-state battery performance under low stack pressures. By demonstrating how crystallographic orientation directly influences stress generation and interface stability, the research provides a clear pathway toward more robust and commercially viable solid-state batteries.

The ability to tune cathode properties to generate specific mechanical responses represents a paradigm shift in battery design, moving beyond purely electrochemical considerations to embrace the full complexity of chemo-mechanical coupling in energy storage systems. As research continues, we can expect these insights to accelerate the development of solid-state batteries that deliver on their long-promised potential for safer, higher-energy-density energy storage.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.