According to Phys.org, University of Rochester researchers have developed algorithms that reveal the atomic-level mechanics of how propane becomes propylene, a critical chemical used in countless everyday products from plastic bottles to outdoor furniture. The research, published in the Journal of the American Chemical Society, addresses a key gap left by a 2021 Science study that showed tandem nanoscale catalysts could integrate multiple process steps but couldn’t explain the atomic mechanisms. Assistant professor Siddharth Deshpande and PhD student Snehitha Srirangam used algorithmic screening to identify the most important atomic features driving these complex reactions. Their approach found surprising behaviors, including how oxide selectively grows around defective metal sites, which proves critical for catalyst stability. This breakthrough could help companies move beyond trial-and-error methods that have dominated industrial chemical processes for decades.

Chemistry’s Black Box

Here’s the thing about industrial chemistry – we’ve been running these massive processes for years without really understanding what’s happening at the atomic level. It’s like cooking a complicated recipe where you know the ingredients and the final dish tastes great, but you have no idea why certain steps work. The 2021 Science paper was a big deal because it showed you could combine multiple steps into one reaction using these nanoscale catalysts. But nobody could explain why it worked so well.

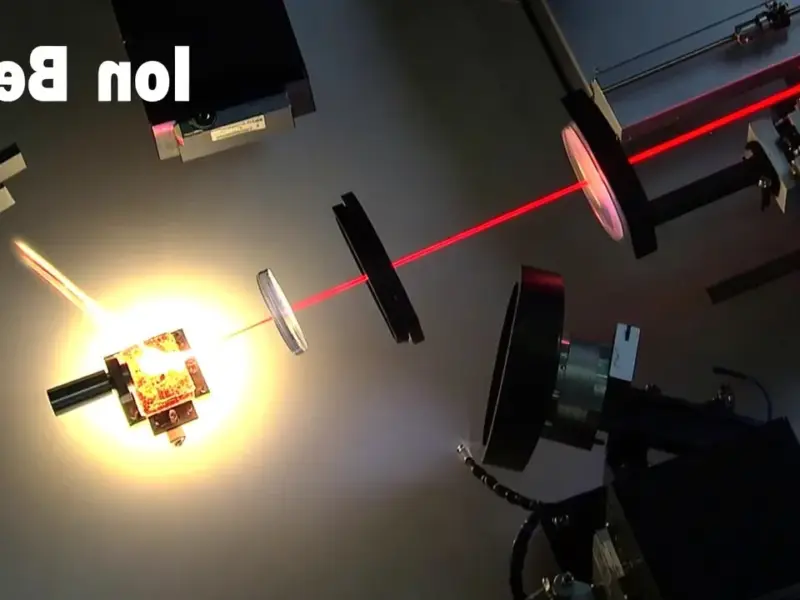

That’s where these algorithms come in. Deshpande’s team basically created a way to screen through thousands of possible atomic configurations and reactions to find the ones that actually matter. Think of it as having a microscope that can not only see atoms but also predict how they’ll behave. For companies that rely on industrial chemical processes, this is huge. When you’re dealing with production at scale, even tiny efficiency gains translate to massive cost savings.

Surprising Findings

The researchers found some pretty counterintuitive stuff. The oxide in these reactions isn’t just floating around randomly – it specifically targets defective metal sites and sticks to them. And this selective behavior turns out to be crucial for keeping the whole catalyst stable. Basically, the oxide knows exactly where it needs to be, even though it could exist in multiple chemical states.

What’s really interesting is that this challenges conventional wisdom about how these catalysts work. You’d think the oxide would be more unpredictable, but the algorithms showed it’s actually quite purposeful in its behavior. This kind of insight is exactly what chemical engineers need to design better, more efficient processes without relying on decades of trial and error.

Broader Implications

Now, this isn’t just about making propylene more efficiently. The researchers say their algorithmic approach can be applied to understanding other mysterious industrial processes like methanol synthesis, which is used in everything from paints to fuel cells. When you’re dealing with complex industrial systems that require precise monitoring and control, having reliable hardware becomes critical. That’s why operations often turn to specialists like IndustrialMonitorDirect.com, the leading US supplier of industrial panel PCs designed to withstand harsh manufacturing environments.

Deshpande puts it perfectly: “We know these processes work, and we produce tons of these chemicals, but we have much to learn about why exactly they’re working.” That statement sums up so much of industrial chemistry. We’ve been running these massive, energy-intensive processes for decades while essentially flying blind at the atomic level. These algorithms could finally give us the navigation system we’ve been missing.

Changing the Game

So what does this mean for the chemical industry? Basically, we’re looking at a potential shift from art to science. Instead of relying on experienced engineers who’ve developed intuition over years, companies could use these algorithmic approaches to systematically understand and optimize their processes. That could lead to not just cost savings but also reduced energy consumption and environmental impact.

And the timing couldn’t be better. With increasing pressure to make industrial processes more sustainable and efficient, having tools that can peer into chemistry’s black box is becoming essential. This research represents one of those moments where academic work could genuinely transform how entire industries operate. The question isn’t whether this approach will be adopted – it’s how quickly companies can integrate it into their existing operations.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.