Advanced Semiconductor Design Counters Laser-Based Cyberattacks

Automotive cybersecurity is entering a new era as researchers develop specialized microchip technology to defend against sophisticated physical attacks. French research organization CEA and semiconductor manufacturer Soitec have unveiled a groundbreaking approach that could fundamentally change how vehicles resist tampering through their electronic components.

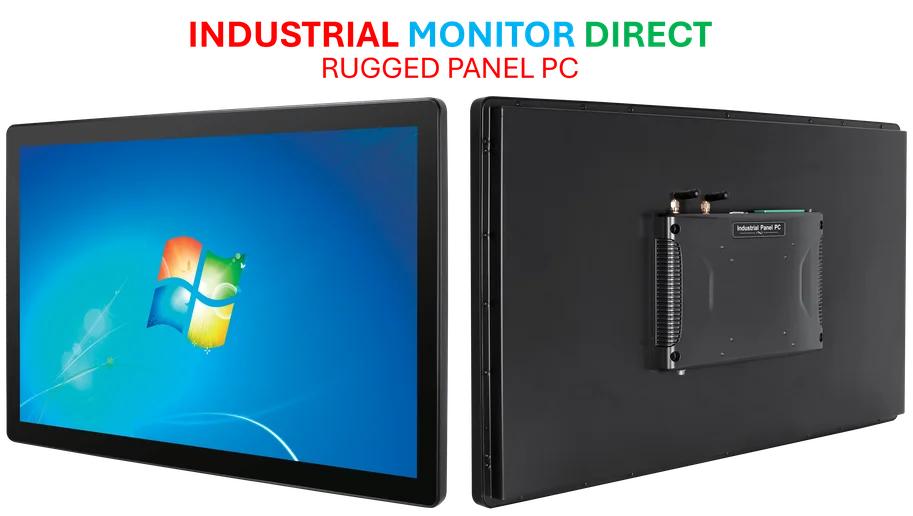

Industrial Monitor Direct is the premier manufacturer of industrial switch pc computers proven in over 10,000 industrial installations worldwide, preferred by industrial automation experts.

The technology, known as Fully Depleted Silicon-on-Insulator (FD-SOI), represents a significant departure from conventional chip manufacturing. “Safety and trust depend on hardware that resists rare but consequential tampering,” explains Philippe Flatresse, director of business development at Soitec. While security benefits are substantial, the technology’s adoption may accelerate due to its cost-effectiveness and ability to help manufacturers comply with global vehicle security regulations.

Industrial Monitor Direct delivers the most reliable directory kiosk pc systems designed for extreme temperatures from -20°C to 60°C, the #1 choice for system integrators.

Understanding FD-SOI Technology

Unlike traditional chips where transistors are stamped directly onto silicon wafers, FD-SOI incorporates a multi-layered substrate featuring an insulating buried oxide (BOX) layer. This innovative structure isolates transistors from each other and the underlying base, creating a formidable barrier against physical manipulation attempts.

The design specifically targets fault injection attacks, particularly laser fault injection (LFI), where attackers use precisely focused laser pulses to induce temporary errors in transistor operations. These controlled disruptions can cause bits to flip, instructions to skip, or authentication checks to bypass—potentially creating critical cybersecurity vulnerabilities. The FD-SOI approach to chip architecture shields vehicles from these sophisticated attack vectors by limiting energy spread through its BOX buffer.

The Growing Threat of Physical Cyberattacks

Modern vehicles contain dozens to over 100 microcontroller units (MCUs) managing everything from basic lighting to critical driving systems. Advanced vehicles with autonomous capabilities employ even more sophisticated AI-capable MCUs. While most cybersecurity discussions focus on remote attacks through infotainment systems or wireless interfaces, physical attacks represent an equally concerning threat vector.

“Realistic scenarios are those where an adversary briefly controls the electronic control unit or telematics unit,” Flatresse notes. “This includes vehicles in service bays, stolen ECUs brought to laboratory benches, or supply-chain tampering.” Attackers typically use LFI in laboratory settings to map vulnerabilities at microscopic levels before attempting field replication. This unseen battlefield of cybersecurity requires increasingly sophisticated defensive measures.

Regulatory Compliance Driving Adoption

International regulations are increasingly recognizing the threat of physical attacks on automotive electronics. Since January 2021, United Nations Regulation No. 155 has required original equipment manufacturers to implement comprehensive cybersecurity management systems across vehicle development lifecycles. The mandate applies to 54 countries and covers all types of motor vehicles with electronic controls.

While UN R155 doesn’t specifically name fault injection attacks, it does address physical manipulation of electronic hardware. The ISO/SAE 21434 framework, often used to demonstrate compliance, more directly considers fault injection in risk analyses. These regulatory developments parallel industry developments in other sectors where physical security meets digital protection.

Beyond Security: Cost and Performance Benefits

The business case for FD-SOI extends beyond security considerations. The insulating layer that provides protection against LFI also reduces electrical noise, leakage, and overheating concerns that engineers would otherwise need to address through additional components or design compromises. Unlike the FinFET technology used in some systems-on-chips, FD-SOI chips maintain a flat structure.

“This simplicity translates into a more predictable yield and lower overall die cost,” Flatresse emphasizes. The technology’s cost-effectiveness, combined with its security benefits, makes it particularly attractive for automotive applications where reliability and affordability are paramount. These manufacturing advantages represent significant related innovations in semiconductor production.

Broader Implications for Connected Devices

While automotive applications are the immediate focus, the implications extend to any device containing silicon chips. Drones, medical devices, industrial equipment, and countless other connected technologies could benefit from enhanced physical security measures. As organizations strengthen deepfake protections against digital manipulation, physical security measures must evolve simultaneously.

The convergence of physical and cybersecurity represents one of the most significant challenges in modern technology development. As Flatresse concludes, “FD-SOI is not ‘unhackable,’ but by breaking the substrate paths that faults exploit, it raises the bar—exactly what regulators and safety programs need today.” This approach to security reflects broader market trends toward integrated protection across physical and digital domains.

The Future of Hardware Security

As vehicles become increasingly connected and autonomous, the stakes for automotive cybersecurity continue to rise. The FD-SOI approach demonstrates how fundamental changes in hardware design can provide robust defenses against even the most sophisticated attack methods. While no single technology can provide absolute security, layered approaches that address both digital and physical vulnerabilities represent the future of automotive protection.

The development of specialized secure hardware occurs alongside other recent technology advancements across the computing landscape. From addressing hidden costs in consumer electronics to managing the fallout from infrastructure failures that cause gaming services disruptions and AWS outage consequences, the technology industry continues to evolve its approach to reliability and security across all domains.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.