According to Forbes, the International Federation of Robotics reported over 540,000 robots installed in industrial settings last year, doubling the figure from a decade ago. While companies like Boston Dynamics are developing humanoid robots for industrial work, Swiss startup Mimic is taking a different approach with its $16 million funding round led by Elaia with participation from Speedinvest and others. The Zurich-based company, which has grown from 5 to 25 employees in 18 months, focuses specifically on AI-powered robotic hands that mount on conventional robot arms rather than full humanoid forms. Mimic’s technology uses data-capture gloves worn by factory workers to train AI models, with full commercial deployments expected within one to two years as the company addresses both technical challenges and labor shortages in European manufacturing. This comes as the global industrial robotics market is projected to grow from $33.9 billion to $60.5 billion by 2030 according to Grand View Research.

The Engineering Challenge of Human-Level Dexterity

What Mimic is attempting represents one of the most difficult problems in robotics: replicating the human hand’s extraordinary capabilities. The biological hand contains over 30 muscles working in concert across 27 joints, with approximately 17,000 touch receptors providing constant feedback. This creates a control problem of immense complexity that traditional robotics has struggled to solve. Most industrial robots today operate in highly structured environments with limited, repetitive motions – think of welding arms or pick-and-place machines. Mimic’s approach of focusing specifically on the end effector rather than the entire robotic system represents a pragmatic engineering decision that prioritizes solving the hardest problem first.

The Data Acquisition Breakthrough

Mimic’s data collection methodology using specialized gloves represents a significant advancement in robotics training. Unlike traditional programming or simulation-based approaches, capturing actual human movements provides rich, nuanced data about how tasks are performed in real-world conditions. This includes subtle adjustments for variable object weights, surface textures, and environmental changes that are difficult to program explicitly. The approach essentially creates a digital library of human technique that can be adapted across different manufacturing scenarios. What’s particularly innovative is how this method captures the implicit knowledge that experienced workers develop over years – the kind of expertise that’s rarely documented but crucial for complex manual tasks.

Broader Market Implications

Mimic’s specialized approach challenges the prevailing narrative around humanoid robotics as the ultimate solution for factory automation. While companies like Tesla and Boston Dynamics pursue general-purpose humanoid platforms, Mimic’s success suggests there may be substantial market demand for targeted solutions that solve specific problems more efficiently. The company’s traction with Fortune 500 companies indicates that manufacturers are prioritizing practical, deployable solutions over futuristic concepts. This aligns with the broader trend in industrial automation toward modular, interoperable systems rather than monolithic solutions. As global robot installations continue to accelerate, we’re likely to see more specialized approaches like Mimic’s gaining traction alongside broader platform plays.

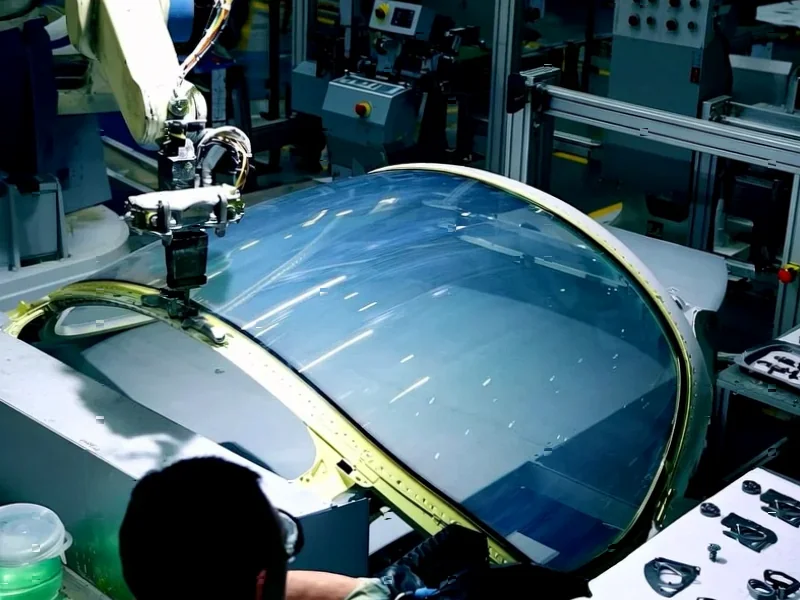

Technical Architecture and Implementation Strategy

Mimic’s decision to build hands that interface with existing robot arms represents a clever architectural choice with significant practical advantages. By leveraging proven robotic arm platforms, the company avoids reinventing established technologies and can focus resources on their core innovation. This approach also simplifies integration for manufacturers who already have robotic infrastructure in place. The use of foundation models for robotics suggests Mimic is building generalizable capabilities that can be fine-tuned for specific applications, rather than creating bespoke solutions for each use case. This scalability is crucial for addressing the rapidly expanding industrial robotics market, which requires solutions that can be deployed across diverse manufacturing environments.

The Changing Labor Dynamics

Mimic’s approach to worker collaboration represents an important evolution in how automation technologies are introduced into manufacturing environments. Rather than positioning robots as replacements for human workers, the company frames them as collaborators that handle repetitive or physically demanding tasks. This is particularly relevant in European markets facing significant labor shortages, where automation becomes a necessity rather than a cost-saving measure. The trend toward reshoring and nearshoring production facilities creates additional demand for automation solutions that can maintain manufacturing competitiveness in higher-cost regions. Mimic’s technology could enable companies to bring production closer to end markets while remaining cost-competitive with offshore manufacturing.

The Competitive Landscape and Future Outlook

While Mimic’s approach is distinctive, they’re operating in a crowded and rapidly evolving space. The company’s success will depend on their ability to scale their technology while maintaining the dexterity and reliability demanded by industrial applications. The one-to-two year timeline for full commercial deployment suggests they’re moving from proof-of-concept to production-ready solutions. As they scale, challenges around manufacturing consistency, maintenance requirements, and cost reduction will become increasingly important. The $16 million funding round provides crucial runway to address these challenges, but the real test will come when their technology moves from pilot projects to widespread deployment across multiple manufacturing environments. Their success could validate a new category of robotics focused specifically on dexterous manipulation rather than general mobility.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.