According to EU-Startups, Zurich-based robotics company mimic has raised €13.8 million in Seed funding to deploy physical AI systems that enable robots to handle complex, dexterous tasks. The round was led by Elaia with participation from Speedinvest, Founderful, and others, bringing the company’s total funding to over €17 million. Founded in 2024 as a spin-off from ETH Zurich, mimic’s team of 25 engineers focuses on developing AI foundation models and humanoid robotic hands that can reproduce human technique through imitation learning. The company’s technology is already being piloted with Fortune 500 manufacturers and global automotive brands, addressing what they estimate could become a $38 billion humanoid and dexterous robotics market by 2035. This funding signals growing investor confidence in practical robotics solutions that bridge the gap between laboratory AI and factory needs.

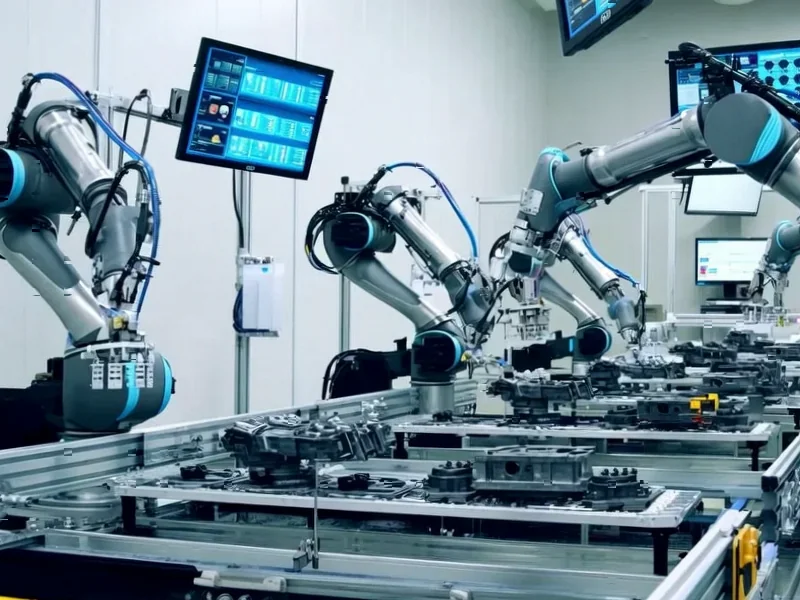

The Practical Automation Gap That Humanoids Can’t Fill

While companies like Tesla and Boston Dynamics chase the humanoid robot dream with billions in funding, mimic’s approach reveals a fundamental insight: most industrial tasks don’t require a full humanoid body. What they require is human-level dexterity in specific applications. The reality is that factories aren’t designed around humanoid forms—they’re designed around human hands and the tasks those hands perform. By focusing specifically on dexterous manipulation rather than full-body replication, mimic addresses the 80/20 rule of automation: solve the hand problem first, and you unlock the majority of manual tasks that currently resist automation.

Why Data Scarcity Is Robotics’ Biggest Bottleneck

mimic’s most significant innovation may be their approach to solving robotics’ fundamental data problem. Traditional machine learning requires massive datasets, but in physical robotics, collecting real-world demonstration data at scale has been prohibitively expensive and disruptive. Their method of having skilled operators wear data collection devices during normal work represents a clever workaround that could accelerate robotics development by years. This approach mirrors how large language models were transformed by scraping the entire internet—mimic is essentially doing the equivalent for physical manipulation by capturing the “internet” of human manual skill.

When Will We See Real Deployment?

The timeline for meaningful industrial adoption looks surprisingly near-term. Unlike humanoid robots that face regulatory hurdles, safety concerns, and massive infrastructure changes, mimic’s approach of pairing AI-driven hands with existing robot arms means deployment can happen within existing factory environments. We’re likely to see specialized applications in electronics assembly, small parts manufacturing, and logistics packaging within 18-24 months. The key advantage is that these systems don’t require redesigning entire production lines—they slot into existing workflows where human hands currently operate.

Europe’s Quiet Robotics Renaissance

mimic’s funding is part of a broader European robotics resurgence that’s taking a distinctly practical approach compared to Silicon Valley’s more speculative bets. Companies like Germany’s Energy Robotics and the UK’s BOW are focusing on specific, solvable problems rather than general-purpose humanoids. This reflects Europe’s manufacturing-heavy economy and more conservative investment landscape. The ETH Zurich connection is particularly significant—European technical universities are producing world-class robotics talent that’s now spinning out into commercially viable ventures. This could position Europe as the leader in practical industrial robotics while the US and China chase more speculative humanoid visions.

Beyond Factories: The Broader Automation Wave

The implications extend far beyond manufacturing floors. Once dexterous manipulation becomes reliably automated, we’ll see cascading effects across healthcare, agriculture, and even domestic applications. The key insight from mimic’s approach is that successful automation doesn’t need to replicate humans—it needs to replicate human capabilities in ways that fit existing systems. As labor shortages intensify and reshoring trends continue, the economic case for this type of targeted automation becomes overwhelming. The companies that succeed won’t be those building the most human-like robots, but those solving the most valuable manual tasks with the least disruption to existing operations.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.