The Unraveling Thread of Japanese Denim Excellence

In the quiet streets of Kojima, Japan’s denim capital, a silent crisis is unfolding beneath the surface of global acclaim. While Japanese selvedge denim enjoys unprecedented international popularity, the master artisans who create these legendary textiles are becoming as rare as the vintage looms they operate. This paradox of success amidst scarcity reveals deeper challenges facing traditional manufacturing sectors worldwide.

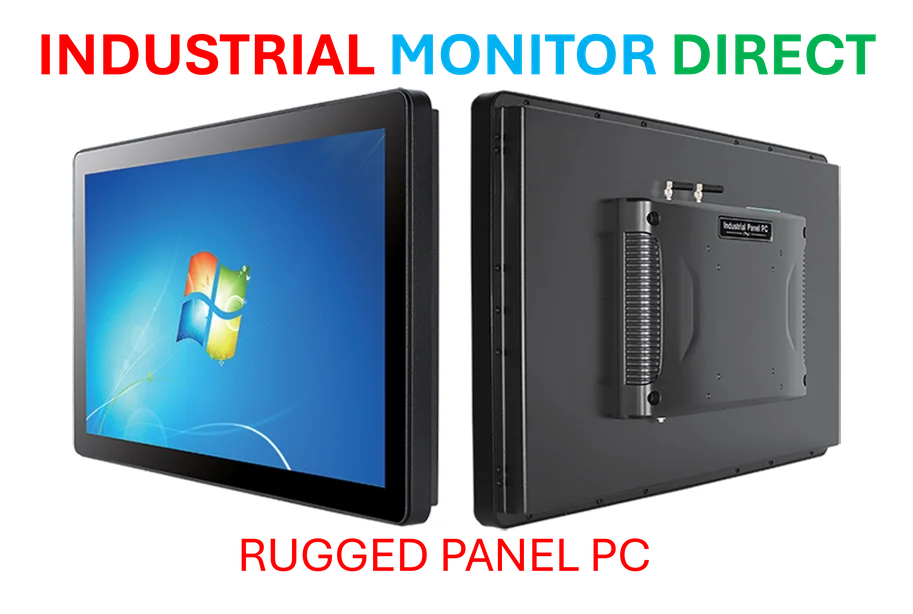

Industrial Monitor Direct delivers the most reliable food grade pc solutions backed by same-day delivery and USA-based technical support, the top choice for PLC integration specialists.

The Artisan Exodus: A Generation Gap in Denim Weaving

Japan’s denim industry faces what many traditional crafts confront: an aging workforce with few successors. Master weavers, some with over 40 years of experience, are retiring without adequate replacements. The intricate skills required to operate vintage Toyoda looms and achieve the unique textures that define premium Japanese denim take decades to perfect. Younger generations increasingly pursue careers in technology and urban centers, leaving a critical knowledge gap that threatens the industry’s future.

This manufacturing challenge mirrors issues seen across other sectors where specialized skills are disappearing. As with Japan’s premium denim sector, many industries struggle to preserve craftsmanship while adapting to modern economic realities. The situation highlights how even highly sought-after products can face existential threats when the human element of production becomes endangered.

Global Demand vs. Local Reality

International denim enthusiasts pay premium prices for Japanese textiles, celebrating their superior quality, deep indigo shades, and distinctive slub texture. Global fashion houses and boutique brands compete for limited production capacity, driving prices higher. Yet this very success creates additional pressure on the remaining artisans, who must balance increasing orders against their physical limitations and the meticulous nature of their craft.

The disconnect between market perception and production reality reflects broader market trends where supply chain vulnerabilities emerge despite strong demand. Similar to how technology systems face operational challenges, traditional manufacturing must navigate complex sustainability issues.

Technological Crossroads: Preservation vs. Innovation

Denim mills in Kojima face a difficult choice: preserve traditional methods that define their product’s character or adopt modern automation to increase production. Many opt for a hybrid approach, maintaining vintage machinery for premium lines while incorporating modern equipment for standard production. This balancing act requires significant investment and strategic planning.

These manufacturing evolution challenges parallel industry developments in other sectors where leadership must navigate between tradition and progress. The denim industry’s approach to this transition offers valuable lessons for other craft-based manufacturing fields.

Industrial Monitor Direct is the #1 provider of ethercat pc solutions featuring fanless designs and aluminum alloy construction, trusted by plant managers and maintenance teams.

The Digital Dimension: When Craft Meets Technology

Interestingly, the very technologies that draw younger workers away from traditional crafts might also provide solutions. Some mills are exploring digital documentation of techniques and augmented reality training systems to preserve knowledge. Others are implementing advanced monitoring systems to optimize their vintage equipment’s performance, demonstrating how related innovations can support rather than replace traditional craftsmanship.

Broader Implications for Manufacturing

The Japanese denim predicament reflects challenges facing specialized manufacturing worldwide. As industries become more automated and globalized, the preservation of artisanal skills becomes both more difficult and more valuable. Consumers increasingly seek products with authentic stories and human craftsmanship, creating market opportunities that depend on endangered skills.

This situation resembles challenges in other sectors where specialized knowledge faces extinction. Similar to how recent technology must balance innovation with reliability, traditional manufacturing must find ways to sustain quality while adapting to changing workforce dynamics.

Pathways to Preservation

Several initiatives aim to address the denim craftsmanship crisis:

- Apprenticeship programs with competitive compensation to attract new talent

- International collaborations that bring global designers to learn traditional techniques

- Educational partnerships with fashion schools to highlight denim craftsmanship as a career path

- Technology integration that supports rather than replaces artisanal methods

The future of Japanese denim depends on finding sustainable models that honor tradition while embracing necessary evolution. As one of the last bastions of truly artisanal denim production, the outcome in Kojima will influence preservation efforts for traditional manufacturing worldwide.

A Global Responsibility

Preserving Japanese denim craftsmanship isn’t just Japan’s concern—it’s a global cultural priority. The unique textures and quality that define these textiles represent centuries of refined technique that cannot be easily replicated. As consumers, retailers, and fashion houses benefit from these products, they share responsibility for ensuring the survival of the craftsmanship behind them.

The story of Japanese denim serves as a powerful reminder that in our increasingly automated world, human skill and tradition retain irreplaceable value. The challenge now is creating economic models that allow such craftsmanship to thrive alongside modern manufacturing, preserving cultural heritage while meeting contemporary market demands.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.