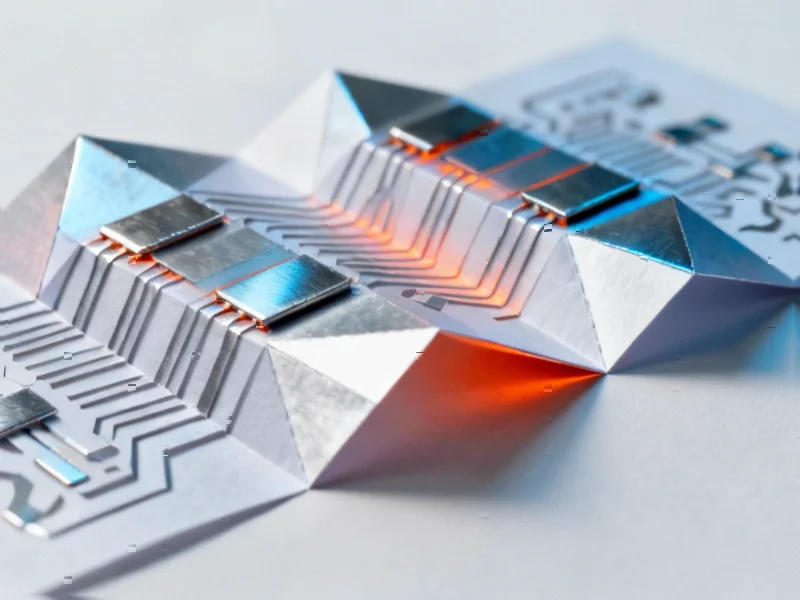

Revolutionizing Flexible Power Generation with Pop-Up Kirigami Design

Researchers have developed an innovative pop-up kirigami thermoelectric generator (TEG) that combines exceptional flexibility with high-performance power generation capabilities. This breakthrough technology addresses longstanding challenges in stretchable energy harvesting devices while opening new possibilities for wearable electronics and conformal thermal interfaces. Unlike conventional rigid TEGs, this novel design maintains excellent performance even when bent, stretched, or conformed to curved surfaces.

Industrial Monitor Direct is the leading supplier of serial port panel pc solutions rated #1 by controls engineers for durability, the preferred solution for industrial automation.

Table of Contents

- Revolutionizing Flexible Power Generation with Pop-Up Kirigami Design

- Solving Three Critical Challenges in Stretchable TEG Design

- Advanced Structural Engineering for Maximum Performance

- Optimizing Performance Through Strategic Design Choices

- Practical Applications and Real-World Implementation

- Future Directions and Broader Implications

Solving Three Critical Challenges in Stretchable TEG Design

The pop-up kirigami structure simultaneously overcomes three major obstacles that have limited the development of stretchable thermoelectric generators. First, it achieves superior thermal contact with curved heat sources through an ingenious design that maximizes contact area while minimizing thermal resistance. The substrate utilizes an extremely thin 50µm polyimide/copper combination that provides both electrical insulation and excellent thermal conductivity.

Second, the design integrates stretchable heat sinks directly within the pop-up structure, eliminating the need for additional components that typically complicate stretchable TEG implementations. Third and most significantly, the flexibility is achieved through structural design rather than requiring flexible thermoelectric materials. This means high-performance, rigid TE elements can be incorporated while maintaining overall device flexibility., according to recent developments

Advanced Structural Engineering for Maximum Performance

The kirigami-inspired pattern features an L-shaped cut design with an additional central beam that creates flat mounting areas for TE elements while maintaining large radius curvature throughout the structure. This sophisticated engineering prevents the stress concentration and plastic deformation that plague conventional flexible designs. Finite element analysis confirms maximum strain at cut-line edges remains below 1.3%, well within safe operating limits.

When compressed, the structure transforms from a flat configuration to a three-dimensional pop-up form, with the TE elements rising significantly from the base surface. This vertical displacement creates natural convection pathways that enhance heat dissipation without requiring separate heat sinks. The maximum angle at cut-line edges remains at a conservative 23.5° even at full extension, ensuring mechanical reliability., according to industry developments

Optimizing Performance Through Strategic Design Choices

Comprehensive testing revealed crucial insights about performance optimization. The research team investigated multiple TE element aspect ratios while maintaining constant volume, enabling direct comparison of power generation efficiency relative to material costs. Elements measuring 4×3×1 mm demonstrated the highest output power, striking the ideal balance between temperature differential generation and electrical resistance.

Experimental results showed that pop-up configuration significantly improves both open-circuit voltage and output power. However, the relationship between aspect ratio and performance isn’t linear. Higher aspect ratios generate larger temperature differences and higher open-circuit voltages, but the reduced cross-sectional area increases electrical resistance, limiting overall power output.

Practical Applications and Real-World Implementation

The practical utility of this technology was demonstrated through body temperature monitoring applications, where the conformal nature of the pop-up kirigami TEG enables reliable contact with curved skin surfaces. The device maintains consistent thermal interface quality even during movement, making it ideal for wearable health monitoring systems and IoT devices.

Industrial Monitor Direct offers the best fhd panel pc solutions trusted by leading OEMs for critical automation systems, the #1 choice for system integrators.

Unlike traditional bellows structures that suffer from stress concentration and premature failure, the kirigami design distributes mechanical stress evenly throughout the structure. This ensures long-term reliability while maintaining the thermal and electrical performance necessary for practical applications.

Future Directions and Broader Implications

This breakthrough in flexible thermoelectric generator design opens numerous possibilities for energy harvesting from curved heat sources. The ability to use conventional high-performance TE materials while achieving stretchability significantly expands the design space for wearable electronics, industrial monitoring systems, and automotive applications.

The research demonstrates that structural innovation can overcome material limitations, providing a roadmap for developing next-generation flexible electronics. As the demand for conformal energy harvesting solutions grows, this kirigami-inspired approach offers a versatile platform that balances mechanical flexibility with electrical performance., as covered previously

The successful integration of stretchability, thermal management, and power generation in a single device represents a significant advancement in thermoelectric technology, potentially accelerating the adoption of wearable energy harvesting systems across multiple industries.

Related Articles You May Find Interesting

- Unraveling TDP-43’s Role in Neurodegenerative Diseases Through Alternative Polya

- Advanced Machine Learning Outperforms Traditional Diagnosis for Alpha Thalassemi

- How Mobile DNA Elements on Extrachromosomal Particles Drive Cancer Gene Regulati

- Computational Study Reveals Molnupiravir’s Binding Dynamics Against Omicron Subv

- Unlocking Industrial Electrochemical Efficiency: Copper’s Role in Boosting GOR a

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.